Clampstar powerline resilience

Engineering out failure: Reinforcing Australia’s grid before the next fire season

Australia’s grid is entering another volatile season — hotter, drier, and under greater load than ever. While much attention falls on vegetation and climate, the quiet risk lies within the network itself: ageing electrical connectors that have endured decades of thermal and mechanical stress.

Electrical connectors degrade over time. Corrosion, thermal cycling, and installation issues can create high resistance, overheating or worse, complete failure. In bushfire-prone regions, that’s not just a reliability concern, it’s a public-safety hazard.

“Reliability isn’t about how fast we rebuild — it’s about how rarely we need to.”

The changing nature of risk

Recent ABC coverage underscores a critical shift: fire seasons in Australia are becoming longer and more intense, and our infrastructure is increasingly exposed ( ABC ). One report noted that failing power lines may have triggered a recent bushfire that burned 11,000 ha and destroyed homes. ABC Failure is no longer an abstract possibility it’s a measurable threat.

As seasonal boundaries blur, asset-managers can no longer afford to wait until after a failure to respond. The modern grid demands a pre-emptive strategy.

What Is ClampStar®?

ClampStar® is an engineered electrical-mechanical shunt, often referred to a Connector Corrector. It is designed not just to repair, but to reinforce and future-proof splices, dead-ends, and suspension clamps without conductor replacement or service interruption.

In effect, it allows utilities to act before failure restoring mechanical and electrical integrity proactively, rather than reacting after failure.

Why it works

ClampStar® succeeds because it’s engineered for both simplicity and endurance.

✅ Rated to 250 °C continuous (tested to 390 °C)

✅ Installs in under 10 minutes with minimal tools

✅ Pre-loaded with CC2 high-temp inhibitor

✅ Torque-limiting bolts prevent over-tightening

✅ Permanent reinforcement that prevents failure

These features matter because the failures we’re trying to prevent are often hidden, rising resistance, heat-spots, micro-arcing; all precursors to larger faults. The ABC article emphasises that technologies and infrastructure must move from “react when it ignites” towards “prevent before it sparks”. ABC

Designed for field reality

ClampStar® units are available for aluminium, copper and ACSR conductors, OPGW and overhead earth wires.

- Distribution networks: light and standard configurations for low-tension spans; optional nickel-plated keepers for copper.

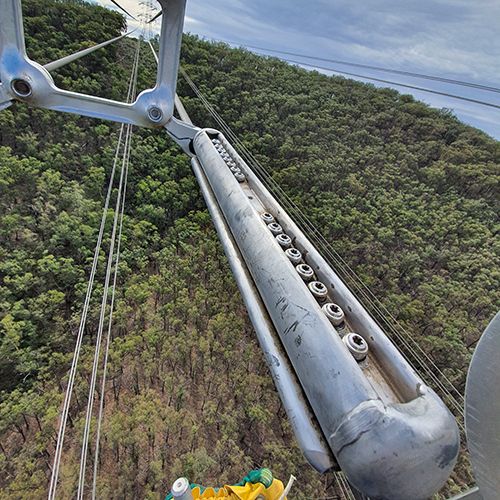

- Transmission systems: heavy and full-tension versions include captive keeper assemblies, Belleville washers to maintain compression, and integrated corona shields.

This is not an off-the-shelf “one-size” fix, it’s engineered for high-stress environments, remote spans, and the harsh climates that typify Australian fire-prone zones.

Applications across the grid

ClampStar® addresses multiple failure modes across live networks:

- Mid-span Joints (CSR Series): Restores integrity, increases ampacity without splice removal.

- Suspension Clamps (CSS Series): Repairs conductor damage at suspension points; Safe-T-Link tether options available for compromised tensile strength.

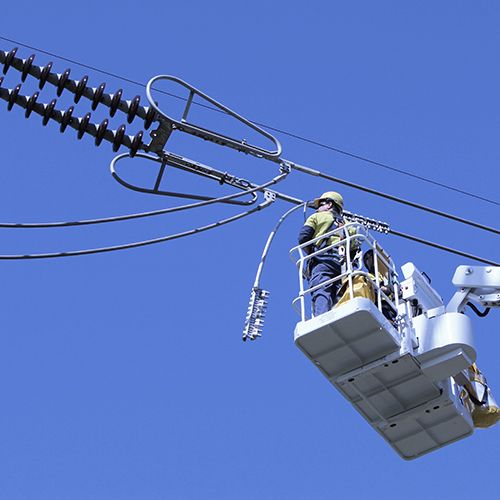

- Dead-Ends (CSS Series): Live installation from basket or helicopter in 15–30 minutes; Safe-T-Link arrests elongation.

- Conductor & OPGW Repair (CRU Series): Live repair of damaged conductors or lightning-struck OPGW outer strands — installs in under 10 minutes.

These targeted applications align perfectly with a preventive asset-strategy: identify the weak links, reinforce them proactively, and eliminate failure as an ignition source.

Pre-emptive approach: Why It matters now

Connector degradation is one of the least visible but most consequential threats to network reliability and fire safety. As recent ABC stories show, ignition from infrastructure failure is real and rising. ABC

ClampStar® gives network operators a tangible way to remove failure points before they fail. This is prevention, not reaction: eliminating arcing, conductor separation and ignition risk; extending asset life; and increasing ampacity where legacy connections limit performance.

In other words, it directly supports the shift from “will we fix it when it goes wrong?” to “we reinforced it so it won’t”.

Economics of smarter reliability

Replacing full spans of conductor is costly, time-consuming and disruptive. Installing a ClampStar® takes minutes, costs a fraction of full replacement, and delivers permanent reinforcement.

The payoff is measurable: fewer emergency call-outs, fewer unplanned outages, longer service life and in volatile fire-seasons, fewer ignition events.

“The smartest engineering isn’t reactive — it’s preventive. The safest line is the one that never fails.”

TEN’s role in Australia’s grid resilience

As the exclusive Australian distributor of ClampStar®, TEN provides utilities, contractors and network planners with local stock, training, and technical guidance. Our focus is helping the industry embed prevention into asset management — not just repairing what fails, but reinforcing what will.

Because in a nation where heat, wind and time constantly test our infrastructure, resilience must be designed in, not rebuilt after the fact. ClampStar® proves that prevention is the most powerful form of protection.

Want to find out more?

Reference:

BOM's first long-range summer forecast shows increased chance of extreme heat - ABC News

https://www.abc.net.au/news/2025-01-27/arthur-river-fire-western-power-damage-powerlines/104863698

https://www.abc.net.au/news/2025-01-20/australia-bushfire-preparedness-new-technologies-drone-ai

Related articles:

https://www.tengroup.com.au/blogs/news/2024/May/31/clampstar-conductor-repair

https://www.tengroup.com.au/blogs/news/2023/Jun/6/ALE_Challenges_2023

https://www.tengroup.com.au/blogs/news/2022/Nov/1/clampstar-article-2022

Copyright © TEN Group | ABN 72 093 052 441