Cable Pulling Lubricants for LSZH and LSHF Cable Jackets

28 Sep, 2020

Cable Pulling Lubricants for LSZH & LSHF Cable Jackets

(Low-Smoke Zero-Halogen & Halogen-Free)

What effect is the lubricant you use having on this jacket?

With ever increasing usage of LSZH jacketed cables on major projects throughout Australia, (Western Sydney Airport, Sydney Metro Rail & Gold Coast Airport to mention a few) the lubricant used is a critical factor in the cable pulling process, over time effecting cable jacket longevity.

Polywater® Lubricants are specially formulated to excel in different cable pulling situations. Application methods targeted lubricity (jacket or conduit), compatibility with specialty jackets, and the pulling environment are all considerations.

Polywater’s lab knows that a focus on one property may affect the performance of another. So, when a lubricant is developed with a specific feature, skill is required to keep the lubricant broadly functional.

This was the case with the development of Polywater® LZ for use on LSZH jacket.

LSZH Jackets

Low-smoke zero-halogen (LSZH) or low-smoke halogen-free (LSHF) cable enjoys growing popularity in industrial, institutional, and commercial construction. This includes all types of cable (electrical, data, alarm, fiber optic, etc.). In a fire, LSZH materials are relatively combustion resistant and they do not release the halogen gases typical of chlorinated and fluorinated jacket materials.

While LSZH is a convenient acronym, it is misleading because there is no single LSZH jacket formulation. In fact, many different chemistries and formulations are used in these jackets. Common, but not universal, is the inclusion of a significant loading of an inorganic salt, typically a carbonate, hydroxide, or borate. This high loading of a non-reinforcing ingredient makes these jackets quite different from traditional carbon-reinforced materials.

The Problem?

Polywater initiated an intensive study of pulling lubricant

interaction after a field-reported LSZH jacket integrity failure. While initial tensile and elongation varies among the test materials, a majority of the LSZH compounds are weakened by specific kinds of pulling lubricants. The changes are the greatest in high-temperature (100° C) soak testing. For a few jacket and lubricant combinations, the effects are so dramatic that the jacket simply disintegrates as is shown in the adjacent photo.

Based on the test results, Polywater concluded that a new

lubricant specifically compounded for these materials is needed in the marketplace. Not only should this lubricant be broadly compatible with LSZH compounds; it must also be combustion resistant without using halogens or heavy metals in the formulation. Plus, it needs superior lubricity on these jackets to produce low tension when the cable is pulled.

LSZH Jacket Compatibility

Because of the great variety of LSZH jackets and chemistries, it is not possible to make generalizations regarding lubricant interaction. To characterize compatibility and develop Polywater® LZ, over 25 different LSZH jacket types were tested using the protocol from IEEE 1210, “Standard Tests for Determining Compatibility of Cable-Pulling Lubricants with Wire and Cable”. The samples included a broad variety of thermoplastic and thermoset LSZH jacket compounds from the US and Europe. The testing refluxes the jacket material in lubricant at several aging temperatures and times (one week to thirty days). Tensile and elongation properties are measured and compared to various controls.

The evaluation began with individual testing of the most common components of modern pulling lubricants. The polar oils and waxes present in most commercially available pulling lubricants are found to affect the more sensitive LSZH jackets. While the details must remain a trade secret, Polywater® LZ was compounded from materials that showed minimal or no effect on the LSZH compounds.

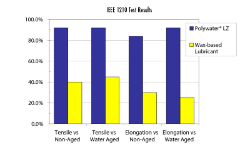

Polywater® LZ shows minimal effect on the physical strength of the LSZH materials tested. For some jacket blends, Polywater® LZ affects these properties less than plain water. The adjacent bar graph contrasts this performance with that of a common wax-base pulling lubricant. Additionally, the wax-base lubricant fails to meet the IEEE 1210 minimums more than half the time.

Polywater worked closely with multiple cable manufacturers in this testing. No other lubricant manufacturer has completed such depth of testing.

Fire and Flame Propagation Properties

LSZH jackets resist burning through char formation on their surface. Lubricant used to install LSZH cables should not affect their critical fire performance.

Earlier research on fire-retardant cables used in nuclear power plants showed that lubricant residues vary significantly in their combustion properties. The residues from wax and oil-based lubricants may burn and spread flame throughout the conduit. While “water-based” lubricants would seem to be combustion resistant, water evaporates and residue properties are key.

Polywater® LZ performs well in fire testing, and does not sustain flame in a heat flux test. Test method details are described in an IWCS paper, “Fire Parameters and Combustion Properties of Cable Pulling Compound Residues”. In the test, lubricant is dried in a horizontal, steel conduit. The residue is subjected to a controlled heat flux, and flame is periodically impinged onto the residue. Ignition and flame behavior over time are determined at various heat flux levels. Wax-and oil residue lubricants ignite, burn, and spread flame at very low heat fluxes.

Polywater® LZ does not sustain flame.

Friction Reduction

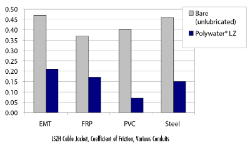

Lubricity is the primary function of a cable pulling lubricant. Not only must the friction coefficient be low, but the lubricant must wet out on the cable jacket and cling for continued lubrication as the cable moves down the conduit. The friction test data in the adjacent bar graph represent averages from several LSZH jacket types. Non-lubricated LSZH shows friction coefficients in the 0.35 to 0.50 range. Polywater® LZ reduces friction significantly on these jackets. This performance compares favorably to other high-performance Polywater® Lubricants.

SPECIFY Polywater® LZ

Polywater® LZ offers unique compatibility with LSZH jackets, superior combustion resistance, and inherently low friction. Polywater® LZ should be specified for any installation where LSZH cables are used.

Download this article in PDF Format here

For further information on the Polywater® LZ, Pull Planner 4.0 and other Polywater® Products contact Lindsay Taylor

Email - [email protected] or mobile - 0400-968-238

|