Cost Effective Asset Life Extension

19 Oct, 2018

If one thing is certain in todays electricity landscape, it is that change is inevitable. The changing landscape of technologies including smart grids, micro grids, distributed energy and storage, renewable energy and demand side measurement and management – are all impacting on authorities’ considerations for new transmission line investment.

Traditionally with lines designed with a lifespan of 40-50 years, what has become abundantly clear is that our energy picture in Australia will look dramatically different in the next 20 years. Add the scenarios of declining peak demand and consumption, “prosumers” and the real potential for grid disconnection – there is a motivating force for the utilities to develop asset life extension methods for transmission networks in these uncertain times.

We are increasingly requested to consider opportunities in product supply that may assist with extending an assets life span by 5,10, 20 years. Even deferring an assets maintenance or replacement timing allows utilities to better manage and prioritise works from the wealth of data coming back from increased access and volumes of infra-red, LIDAR ad UV inspection technologies.

WHAT ARE THE CHALLENGES

Specifically at deadend towers and their termination connections, the impacts of our harsh Australian environment take their toll on ageing dead end connectors. Moisture ingress, corrosive salt conditions, thermal expansion and contraction, potentially under or over crimped connections and increased loads since construction all have a significant impact on the conductor condition at the joint interface. The resulting heat generated by a worn connector and conductor result in a hot joint that breaks down the mechanical and electrical strength of the connection over time – the ultimate outcome, if no intervention is made, is a catastrophic failure.

In regards to the surrounding infrastructure, conductors and a well maintained tower will always outlast the connector. The ability to apply a maintenance or permanent solution to the challenge can extend the line asset by up to 30 years, maximising its potential service life.

TRADITIONAL METHODS

There are three main options for replacing a failing dead end.

1. Build a new line (or restring existing) – expensive and resource intensive

2. Cut out the affected dead end, splice in a new section of conductor (typically 10 metres back from the deadend) and reconnect with a splice and new dead end connector – resource intensive and there is now two potential failure points

in a small section of line

3. Cut out the dead end, terminate a new dead end and replace insulator with a longer string – two to three phases per day, requires new insulators and jumpers

Additional considerations to the above methods are rigging requirements, access requirements, helicopter costs (if used), costs associated with de-energising and resources required if working live. Ultimately, the resourcing costs are the critical line items to control in any program of works.

NEW SOLUTIONS

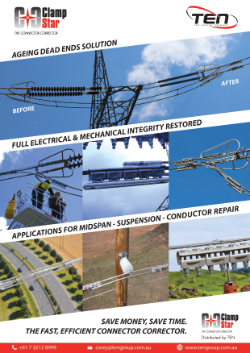

Classic Connectors have developed a revolutionary electrical and mechanical shunt. The ClampStar units are designed to have a total resistance less than the main line conductor and splice combined. This allows the ClampStar shunt to direct the current and mitigate temperature issues, and restore the mechanical integrity to its original strength, preventing potentially catastrophic dead end failure. The ClampStar dead end assemblies can be installed from a helicopter or basket, working live, in as little 15-30 minutes. This is a considerable saving in the time and resources to rectify a failing dead end.

Each unit is prefilled with proprietary CC² inhibitor to prevent galvanic corrosion and is designed with an integral fastening assembly that provides a high conductivity path and incorporates flat and Belleville washers to maintain compressive force regardless of thermal contraction and expansion. Installing a ClampStar® over the deadend assembly, provides assurance that the entire electrical and mechanical load will be maintained indefinitely.

On a deadend application, the restoration of mechanical integrity is accomplished with the Safe-T-Link tether. This is a steel cable with threaded rods attached to each end, which are inserted into receivers on brackets, one attached to the steel eye component of the deadend and the other attached to the ClampStar unit. The purpose of the tether is to “arrest” any possible elongation of the original deadend, not to relieve the present tension – but just enough to make the tether “taught” removing any slack. Thus, for any elongation to occur to the original connector, the existing tension would have to increase enough to overcome the tether first.

MANAGING CORONA OVER 132KV

Corona is a phenomena associated with transmission lines, typically over 132kV. It results from a leakage of electrical current into the air surrounding a conductor and hardware (usually from a sharp point), causing the air molecules to ionise and become conductive – this not only results in power loss but can damage hardware over time. ClampStar units are available with corona shields that slide over the bolt ends - these distribute the electric field gradient and prevent/control the corona discharge protecting the hardware components.

AN AUSTRALIAN TRANSMISSION CASE STUDY

In late 2017, an Australian Transmission Authority installed over 400 ClampStar units to extend the life of several critical 330kV lines. Inspection programs had identified bulging dead ends exhibiting increased resistance on a line built circa 1960’s. The authority went about planning for replacement of all the dead end joints (and insulators) as part of a preventative maintenance program - aiming to keep the line in service without restringing or building new. Traditional methods (cut and splice) would result in completion of only 1 to 3 phases per day (site conditions dependent) and a long program of works. After extensive review of the ClampStar product, an engineering and project management decision was made to utilise this new, innovative solution to permanently rectify the issue at hand for the remaining life of the conductor - saving time, money and minimising outage time. The program was completed successfully, at a rate of multiple towers per day with a dramatically expedited program of works compared to traditional methods. Field feedback was extremely positive with the ease of install and safety benefits of the ClampStar appreciated.

For more information on the developed solution and how it may benefit your asset management program, please contact Classic Connectors exclusive Australian, New Zealand and Pacific Islands distributor, Corey Scott of TEN Group – 0419 729 026.

|