TEN Offers a new lease of life with refurbishment

14 Feb, 2018

TEN's Jeff Gregory offers an insight into the stages of refurbishment

Tesmec is the leading provider of transmission stringing machinery in the Australian and New Zealand market. The Italian made machinery has been designed to withstand the tough conditions in which they operate around the globe. Australia gives machinery as good a test as most, however just like servicing your car, its important to keep on top of maintenance to keep your plant running optimally and reliably. After many years of service, a machine refurbishment is a great option to reset the clock both mechanically and aesthetically. This is no different to bucket trucks or mining plant.

So where do we start with the refurbishment of hydraulic machinery? This article explains the process of a TEN refurb on stringing equipment.

Why do hydraulic machines require such a detailed overhaul?

Meeting a stringent set of OEM standards often requires extensive component replacement but as our machinery fitter Jeff Gregory explains, the long-term reliability and safety of equipment is of highest consideration in the refurb of any machine.

TEN approaches each machine refurbishment from a manufacturers viewpoint on performance and safety. Our technicians work to OEM standards to ensure every machine leaves the factory ready to be deployed in the field.

Hydraulic machinery operates under extreme conditions in our environment. Not just the heavy loads they have to pull, but also the high temperatures, dusty conditions and extensive transport around the country.

Every aspect of the machine is considered under the refurbishment plan. We test, measure and evaluate for repair or replacement.

With highly engineered pumps, valves, and controls it is necessary that repaired units and components perform with the same efficiency and operate as close to the original as possible.

Jeff further explains the process of bringing a machine back to its former glory and performance.

“Each machine is visually inspected on-site to assess the type of refurbishment. In consultation with the client, we discuss the extent of the rebuild and repairs to each aspect of the machines operating systems. We talk through potential upgrades to software, mechanical systems, options and guarding. Every machine is inspected and evaluated and then costed for refurbishment.”

Whilst we go to great lengths to ensure everything is taken into account, we will provide a second inspection and continuous communication with the customer to ensure we keep on track and on budget.

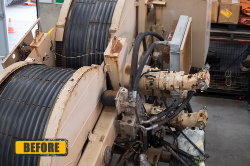

Our latest refurbishment for a large national contractor included a Tesmec AFS500 and FRB501. Click on images opposite to see the before and after photos of the AFS 500

Included in our services were the engine service and diagnostics, a complete overhaul of hydraulic hoses, fittings and control valves. Electrical safety upgrades were performed along with replaced relays and a performance test to assess the success of the full refurbishment. We upgraded with bull wheel guarding and gave these machines a fresh coat of 2pack paint, replacing safety labels and markings to complete the process.

“Customers often mention how good they look when they are delivered back. We’re comfortable in the knowledge that our refurbishment program will deliver a machine that performs as good as it looks”

There is no doubt the TESMEC machines are originally built to withstand the rigours of service within the Australian environment but every machine could use some TLR (that’s TEN’s Leading Refurbishment) at some point in its extensive working life.

If you would like more information on this service, please give Corey Scott a call on 07 3212 8999.

|