- TEN's next chapter

20 Jan, 2026 - Choosing the right Insulation Resistance Tester

3 Dec, 2025 - Driven to do right: TEN’s $10K gift opens new possibilities for Kedron Lions AFL

15 Oct, 2025 - National Safe Work Month

7 Oct, 2025 - La Granja Glass Insulators

29 Aug, 2025 - TEN backs Australia’s energy future with LaGranja Insulators

5 Aug, 2025 - 500 days injury free at TEN: that’s the sound of success

29 Jul, 2025 - Supporting Canberra's utilities with tooling solutions

7 Jul, 2025 - TEN Achieves "Beyond Best Practice" in FY24 APCO Annual Report: A sustainability milestone

26 Jun, 2025 - Neil Bartlett retires after 47 years: A legacy of excellence in Australia’s Utility Networks

22 May, 2025 - TEN becomes the exclusive Australian importer and distributor for Salisbury Electrical Safety products by Honeywell

12 May, 2025 - Cyclone Alfred

15 Apr, 2025

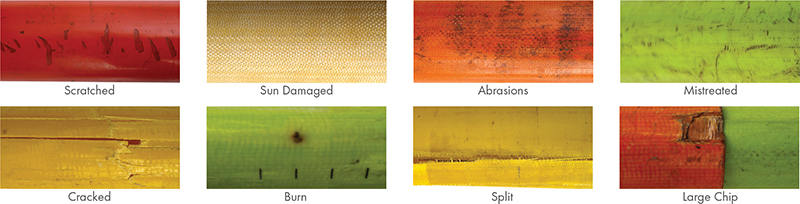

Handy Guide for Fibreglass Stick Maintenance26 Oct, 2021 Fibreglass Equipment Inspection, Cleaning & MaintenanceLive line tools should be visually inspected daily before use for defects such as abrasions, blemishes, burns and surface deterioration. Any defect is cause for rejection as it may impair the dielectric integrity. Rejection does not mean discarding the tool, only removing the tool from service and tagging. Common stick defects to look for

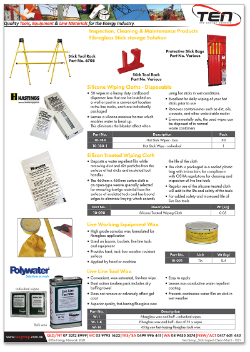

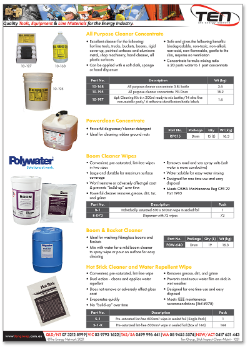

Hot Sticks and Fibreglass Care & MaintenanceFor instruction on how to clean hot sticks, watch our video by scanning or clicking the below QR code. Or download “Advice for the Care and Maintenance of Your Equipment” by clicking this link: https://www.tengroup.com.au/blogs/news/2020/Apr/7/ten_care_and_maintenance For stripping back heavy contamination and prior to re-waxing, use the Hastings All-Purpose, Safe, non-toxic, biodegradable, PH neutral & non-flammable Cleaning Concentrate (10-195). Once the surface has been cleaned thoroughly, it is critical to re-wax the stick. The Polywater® Fibreglass Wax and Buff Kit is a simple, easy to use, one application wipe ideal for this purpose. It should be noted, waxing is best done after a thorough stick cleaning. Use of wax products over contaminated surfaces only locks the dirt in. For spot cleaning the sticks and daily before use, the Polywater® Water Repellent Wipe (Part S-1) that (contains a minimum 60% isopropyl alcohol and silicone) helps clean and restore the water beading properties of the stick. After extended periods of use and exposure to the elements your stick surface may require maintenance. Unless the tool is mechanically damaged your stick may be able to be repaired. For washing booms, use the Polywater® Fibreglass Wash (FGW-640). This replaces the previous (BWC) Boom Wash Concentrate. Download the Stick Inspection and Cleaning Guide Here |

|

Copyright © TEN Group | ABN 72 093 052 441