- TEN's next chapter

20 Jan, 2026 - Choosing the right Insulation Resistance Tester

3 Dec, 2025 - Driven to do right: TEN’s $10K gift opens new possibilities for Kedron Lions AFL

15 Oct, 2025 - National Safe Work Month

7 Oct, 2025 - La Granja Glass Insulators

29 Aug, 2025 - TEN backs Australia’s energy future with LaGranja Insulators

5 Aug, 2025 - 500 days injury free at TEN: that’s the sound of success

29 Jul, 2025 - Supporting Canberra's utilities with tooling solutions

7 Jul, 2025 - TEN Achieves "Beyond Best Practice" in FY24 APCO Annual Report: A sustainability milestone

26 Jun, 2025 - Neil Bartlett retires after 47 years: A legacy of excellence in Australia’s Utility Networks

22 May, 2025 - TEN becomes the exclusive Australian importer and distributor for Salisbury Electrical Safety products by Honeywell

12 May, 2025 - Cyclone Alfred

15 Apr, 2025

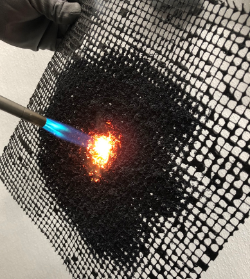

Fire Hardening Wood Pole Assets22 Oct, 2020 Genics Inc is a renowned wood science company with a dedicated focus on all aspects of utility asset pole including test and treat, pole asset management software and Fire Mesh™ (patent pending). Two brothers Wesley and Calvin Wall have been working with utility asset poles for 40 years, now their passion for innovative products with safe chemical profiles translates into a strong competitive advantage for Genics Inc. The unprecedented scale of bushfires in recent fire seasons across Australia, Canada and the West Coast of the USA, has highlighted the need for proactive wood pole life management in fire prone areas. Ultimately, preservation is key. Maintaining a functioning network in the midst of a natural disaster is critical. Genics Inc sought to develop a pole protection product that was easy to apply, required no ongoing maintenance, would not contribute to pole degradation over its life, and that provided superior fire mitigation performance. Driven by science and a passion to innovate in this space, Genics Inc worked closely with many utilities and research facilities to bring Fire Mesh™ to the market. Optimum Design, Maximum Protection The increased threat of fires brings into question the use of wooden assets for electricity transmission and distribution in fire prone areas despite being made from a plentiful and renewable resource that sequesters carbon. After more than a decade of research and development, the evolution of fire-retardant products designed to protect wood poles led to “paint on” and wrap products that are applied to the surface of the pole. Whilst effective in mitigating the risk of fire catching, these products introduced new risks to pole management through moisture retention and inadvertent coating damage that reduced effectiveness. Genics Fire Mesh™ is a protective barrier designed to protect structures from wood burning and scorching. It is vital for a wood pole to achieve equilibrium and homeostasis with the climatic conditions associated with its placement, therefore, the best product solution is one that promotes air exchange and allows the pole to breathe. The Fire Mesh™ is designed with an open grid that allows visibility of the timber behind it, and most importantly, allows the pole to breathe. Combining state of the art polymers with innovative fire-resistant compounds, Genics Inc was able to create a very durable and high performing intumescent grid that has achieved excellent fire resistance in many standardized tests and controlled burns. The mesh is extremely durable and can be applied to new poles before transport to fire prone areas. There is also a favourable environmental and safety profile, the product is animal safe, there is no leaching of chemicals and it is safe to handle. Extensive Testing Timber power poles are exposed to three heat/fire conditions in the event of a fire. Firstly, an intense heat and winds ahead of a fire front that primes timber to burn by raising temperature and evaporating moisture, then the fire itself which is a function of prevailing conditions and vegetation fuel loads in proximity, followed by the smouldering and heat profile that remains once the fire passes. Any assessment of a product must be considered in respect to the response and impact during these stages. The Western Fire Center is a testing facility located in Kelso, Washington, USA. They have a draft ASTM standardized test that is developed to simulate wildfire conditions and it is one of the toughest fire tests for materials to pass. A 2.1m pole sample is exposed to a radiant heat panel (See image 2) set at 980°C (Heat flux of 50 kW/ m2) for 5 minutes. After the 5 minutes, a ring burner set at the base of the pole is ignited for an additional 5 minutes along with the heat panel. The test is concluded either when the temperature of the test specimen drops below 50°C or if the specimen goes to failure and burns. The temperature of a pole wrapped in Fire Mesh fell below 50℃ only 8 minutes after the removal from the flame and 980°C panel. The control sample in this same test was deemed to have undergone catastrophic failure, and it remained above 50℃ for over 4 hours. After several tests using different species, age of poles, initial treatment of poles, it was found that poles wrapped with the Fire Mesh indicated that no flame was sustained beyond the removal of the ring burner. Damage to the poles were so minimal that there was no effect to the overall strength of the pole. Strength loss is calculated based on concentric and unicentric calculation and char depth analysis. The product has been extensively tested to this draft ASTM Wood Pole Fire Test Standard, accelerated weathering testing to determine UV performance, and is Intertek tested and listed. Recent real world experience Several controlled burns have also been conducted in different climatic zones along with burns of simulated wooden trestle bridges for railroad companies. In all of these tests, the Fire Mesh has proven to be very effective and successful at protecting the wrapped structures from ignition and breakdown from fire. Perhaps the best example of true bushfire conditions were the simulated forest fires carried out by FP Innovations in conjunction with the Canadian Government where two identical cabins were built, one was wrapped in fire mesh and the other left bare timber. Refer image 3 that demonstrates the effectiveness in protecting the structure. At 149°C, the intumescent barrier begins to expand and seals off the timber from any strength loss or damage to the wood during a fire. It works against a fire by cutting off the oxygen to the surface, limits the heat exposure and reflects the heat as a result of the embedded graphite in the intumescent polymer. Recently, a series of wildfires on the West Coast of America severely impacted power utilities in California. One utility that was proactively installing wood poles with Fire Mesh™ in high risk areas has now experienced the real world benefits of this proactive approach. Whilst on-going surveying and damage analysis continues in the fire, Genics Inc has been notified that only one wood pole had to be retired for fire damage (the flame heights had reached higher than the protected wrap zone of 6 metres). The utility is very pleased with the performance of the Fire Mesh and of their investment in proactively protecting their assets in high fire areas. Their proactive approach has been commended and approved by the Utility Commission and the rate payers alike. They have also filed a senate bill in early 2019, once testing and standardisation had begun, informing congress that they will continue to wrap and protect wood poles in high fire areas. Initial installation in high fire risk zones, and on crucial feeders such as those to Dams and potentially isolated communities is an excellent use case for fire mesh trials. Fire Mesh is a proven, effective and economical solution to a fire risk for utilities, railroad and construction companies. TEN is proactively stocking fire mesh for Australian utilities ahead of another fast approaching fire season. For more information on the fire mesh and its potential application in your utility, contact Lindsay Taylor on 0400 968 238 or [email protected] |

|

Copyright © TEN Group | ABN 72 093 052 441